While chipmakers enhance the functionality of semiconductor devices and increase multi-functionality, they need to reduce development times. Advantest's T2000 is ideal for testing these devices.

Time to Market Reduction - Multi-Session

The T2000 makes it possible to develop device test programs efficiently with minimal investment. With the multi-site CPU architecture unique to the T2000, multiple users can log in to a single test system at the same time, and perform debugging work independently. Up to eight people can work simultaneously, contributing to both engineering cost savings and TTM reduction. In addition, eight people can develop separate functions for the same device concurrently, which greatly shortens development times.

Best-In-Class Parallel Test Efficiency - Multi-Site Controller

As more DUTs (Devices Under Test) are measured simultaneously, overhead tends to increase, and test times in general tend to be longer. However, the T2000 reduces test time and achieves high throughput with highly efficient multi-site test technology that completely eliminates overhead.

Test Time Reduction - Concurrent Test

The T2000 supports concurrent test functionality which can execute complex device test in shorter times. Concurrent test can be more easily achieved than in the past, as the T2000 can seamlessly switch between sequential execution and parallel execution of multiple test items. In addition, its concurrent test functionality enables users to rapidly develop test programs with short test times.

Test Cost Reduction

With up to 8,192 digital channels, the T2000 achieves more than twice the parallelism of the previous model, reducing test cost.

T2000 Product Lineup

Software

- Windows Based Operating System. Easy to Use. Easy to Customize.

- Rapid Development Kit (RDK) Environment: Easy Coding, High Code Reusability, and Fast Debug.

- Versatile Offline Environment: Thorough T2000 System Software Emulator.

- Abundant Tester Tools: Wave Tool (Logic Analyzer, Oscilloscope), Shmoo, Pattern Editor, etc.

- Instrument Slicing, Test Condition Runtime Optimizer, Multi-session, Concurrent Test Flows.

SoC Test Solution

High-performance, low-cost SoC test solution optimized for high-volume manufacturing of today's complex consumer devices.

Achieve feature-rich capabilities with high precision

Analog modules provide broad coverage.

In the ever-evolving digital consumer market, devices are becoming more sophisticated and diversified in terms of functionality with:

- Multi-Time Domain functionality for testing several frequency domains simultaneously.

- 1GDM / 1.6GDM realizes low cost of test by high parallel testing.

- DSP192A module supports 96-ch device power supply by high density mounting.

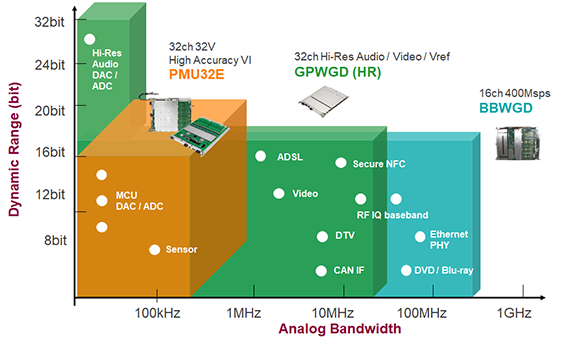

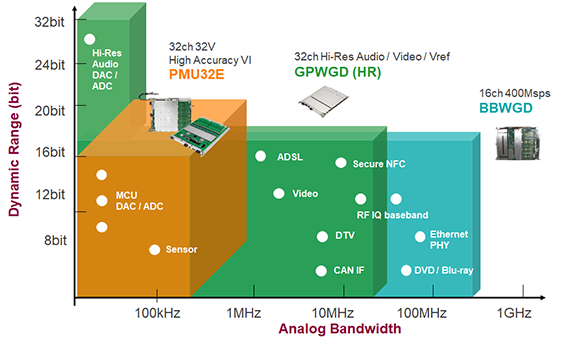

- Analog modules (BBWGD/GPWGD) full-spec test, covering high-performance audio to video and baseband.

- PMU32E module capable of handling a broad spectrum of precision test including ADC/DAC linearity.

- 8GDM corresponds to high-speed interface device testing.

Flexibly combined with these test modules, T2000 provides customers with an optimized test solution for consumer devices.

Wireless Test Solution

Next-Generation Solutions for Wireless Communication Systems

Fully Integrated Single Module "WLS32-A" with 4 Unique RF Vector Signal Generators and Analyzers

- High-performance VSG and VSA instrumentations supporting complex modulation densities up to 80MHz bandwidth

- Fast test times achieved with fast settling synthesizer switching

- Highest industry RF port density (32 per module and scalable to 128) for today's and tomorrow's multi-DUT MIMO and transceiver applications, which supports high parallel testing

- High-speed & high carrier to noise ratio synthesizer modes to address production and characterization solutions

- Built-in low-noise, low-jitter programmable reference signal generator for reference signal input

- Internal highly linear 2-tone combiner to produce > +28dBm (@2.2GHz, -12dBm) output IP3 to device

- Lowest COT achieved with quad-DUT native capability (parallel source and measure)

Integrated Power Device Test Solution

We provide solutions for high-performance, high-throughput testing of devices for automotive, industrial and power management applications.

Setting a New Standard

- High flexibility and ease-of-use due to a multi-functional mixed-signal architecture.

- Low cost of test with high parallelism.

- Increased throughput with pattern-controlled test conditions.

- Enhanced test efficiency using per-channel time measurements.

- Simple load board Design by Cross function port and matrix functionality.

- Best-in-class performance, including fast range switching hardware, fast switching relays and concurrent hardware operation.

- Simplified coding enabled by the rapid development kit (RDK) software package, which provides a user-friendly environment for developing reusable code and implementing fast debugging.

- Wide coverage for testing on the same platform, from low-voltage communication PMICs to high-voltage automotive ASSPs.

Optimized Modules for Power Mixed Signal Test

CMOS Image Sensor Test Solution

We provide a test solution that minimizes test cost, by flexibly supporting measurement of the most advanced CMOS image sensors with a high-speed interface.

Flexible support for multifunction image sensors

CMOS image sensors have a variety of built-in functions including AD/DA and logic circuits.

By combining measurement modules, The T2000 can achieve a scalable system configuration with the functions required for image sensor testing.

High speed Image capture up to 4.8Gbps

Equipped with a high-speed image-capture interface that supports a variety of CMOS image sensors, providing higher precision, higher sensitivity, and greater speed for products that utilize such sensors, including mobile, security cameras, and automotive/industrial cameras.

Dual bank high-capacity capture memory stores data and transfers data to the IP Engine at the same time, minimizing the test time.

- Differential Input

MIPI D-PHY V2.1 : 4.8Gbps

MIPI C-PHY V1.2 : 3.5Gsps - Capture Memory : 1,024M pixel x 2bank

Available to store max. 64,000 frames of the image data to the memory

It can capture CIS image data quickly and efficiently when used in combination with our high-speed image processor engine IPE3 (Image Processor Engine 3).

Test cost reduction by Maximum 64 DUT Parallel testing

The T2000 can measure multiple DUTs simultaneously, improving the productivity of image sensor chips and reducing test costs. With a wide user area and a light source with an enlarged irradiation area of 160 mm by 150 mm, it can perform parallel measurement of up to 64 DUTs.

T2000 module configuration for CMOS image sensor testing

Scalable System Configuration

| | R&D, Small Lot Production | Mid Volume Production | High Volume Mass Production |

| |  |  |  |

| Parallel Test | 16 | 32 | 64 |

| Main Frame | LSMF | LSMF | LSMF+EXMF |

| Test Head | 13 slot | 46 slot | 46 slot |

The T2000 makes it possible to have a scalable system configuration ranging from an air cooling system with 9 slots to a liquid cooling system with 52 slots and up to 8,192 channels.

We provide compact solutions with reduced initial investment for development and small lot productions and high-efficiency multiple-DUT parallel measurement solutions for mass productions. With the T2000, we can recommend the optimal configuration for your measurement needs.

T2000 Today

T2000 AiR Overview